the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

Research on surface integrity of AISI M2 workpiece hard-turning precision machining with cubic boron nitride cutting tool

Linsen Zhao

Tao Chen

Jiali Liu

To investigate the surface integrity of AISI M2 workpieces during hard turning with a cubic boron nitride tool, the surface morphology, metamorphic layers, and mechanical properties of 18 hard-turning experimental samples were characterized using scanning electron microscopy and other analytical instruments. The results showed that the machined surface morphology had good consistency, but there were defects such as turning grooves. The turning feed had the most significant influence on the three-dimensional surface roughness Sa: when the feed rate increased from 0.05 to 0.2 mm r−1, Sa increased from 0.824 to 5.795 µm. When the turning speed was lower than 200 m min−1, the white layer thickness was positively correlated with the turning speed (approximately 0.32 µm at 200 m min−1), while a negative correlation was observed when the speed exceeded 200 m min−1 (approximately 0 µm at 360 m min−1). As tool wear increased from 0 to 0.2 mm, the white layer thickness increased by 143.75 %. The surface residual stress was mainly compressive stress, with the maximum axial compressive stress (−72.1 ± 7 MPa) observed at a turning speed of 160 m min−1. The metamorphic layer significantly increased the surface hardness. This study provides a reference for improving the service life of AISI M2 workpieces.

- Article

(5253 KB) - Full-text XML

- BibTeX

- EndNote

Precision machining is a practical scientific technology closely related to people's production and life. It undertakes the processing of parts required for various civilian and military equipment. It is an important manifestation of a country's comprehensive competitiveness. The advanced precision manufacturing sector demands that machining technology not only achieves precision and intelligence but also progresses gradually towards green and sustainable development. Hard cutting technology has the outstanding advantages of environmental friendliness and resource conservation, and it is a green precision manufacturing technology that has been widely considered (Cakan et al., 2024).

Hard turning, as a precision machining technology, refers to turning a hardened workpiece with hardness greater than 45 HRC as its final precision machining process (Çetindağ et al., 2024). This machining method can replace the traditional precision grinding technology, realize “turning instead of grinding”, and improve the machining economy of the workpiece. This machining method has become the main precision machining method for high-hardness and difficult-to-machine materials (Mane et al., 2025). In hard turning, the tool produces high friction, extrusion, and shearing effects on the workpiece, which results in a lot of cutting force and cutting heat in the cutting process. The transmission of cutting force and cutting heat makes the workpiece surface bear gradient load, which affects its surface integrity. Surface integrity is a comprehensive and detailed description of the machined surface of the workpiece, which includes surface morphology, metallographic state, and surface mechanical characteristics.

The surface integrity of a workpiece exerts a significant influence on its performance throughout the entire service life cycle (Zhang et al., 2025; Paengchit and Saikaew, 2023). Numerous researchers have conducted many investigations on workpiece surface integrity in hard turning. Sales et al. (2020) reviewed the surface integrity of hardened steel during hard cutting by case analysis and investigated the causes of residual stress, a white layer, and micro-defects on the machined surface. Sivalingam et al. (2021) explored the surface integrity of Inconel 718 under dry machining and atomized spray cutting fluid machining separately. Although cutting fluid machining achieved good surface quality, there were still feed marks and burned surfaces on the workpiece surface. Feed rate was the primary factor influencing the surface roughness of Inconel 718 under both machining methods. Considering the influence of surface integrity on rolling contact fatigue life, Jouini et al. (2020) studied the roughness, residual stress, and surface morphology of hard turning AISI 52100 bearing steel. The experimental results of hard turning were as follows: the surface roughness was less than 0.1 µm; the maximum stress, i.e. compressive stress, appeared between 10 and 50 µm below the machined surface of the workpiece; and the thickness of the white layer was less than 1 µm. Li et al. (2018) discussed the influence of the tool cutting edge radius on the surface integrity of an AISI H13 workpiece during hard cutting. The research conclusion indicated that the nano-hardness, plastic deformation depth, and compressive residual stress of the machined surface increased with the increase in cutting edge radius, but the white layer structure was not found. Branco et al. (2018) analysed the surface integrity of AISI 4317 carburized steel during hard turning. There were compressive residual stress and a white layer on the machined surface. The white layer was produced when the cutting temperature was lower than the austenitizing temperature of AISI 4317, and the cutting feed was positively correlated with the thickness of the white layer. More and more scholars are paying attention to the influence of the turning parameters of hard turning on surface integrity indexes, such as surface morphology (Zhou et al., 2024), microhardness (Dash et al., 2021), residual stress (Elsheikh et al., 2022), and surface metamorphic layer (Zhang et al., 2021).

In this research, AISI M2 was mainly used to machine the valve core of a high-pressure common rail single pump of an engine, which operated in complex working conditions. Therefore, it is essential to investigate the surface integrity of the AISI M2 workpiece during hard turning. Although many scholars have researched the surface integrity, they have not explored the surface integrity of the AISI M2 workpiece during hard turning. The main purpose of this research is to analyse the influence of hard turning parameters on the surface integrity of the AISI M2 workpiece to improve the service life of the AISI M2 workpiece under complex working conditions and enrich the surface integrity research of hard-turning precision machining.

2.1 Workpiece material and experimental instruments

AISI M2 is a high-carbon steel with high hardness, high wear resistance, and high heat resistance, also known as high-speed tool steel (Hacisalihoglu et al., 2017). The blank of the AISI M2 workpiece is cylindrical, with a diameter of 10 mm and a length of 100 mm. After being subjected to quenching and tempering treatments, the workpiece has a hardness of 62 ± 1 HRC, a yield strength of 1350 MPa, and a tensile strength of 2280 MPa.

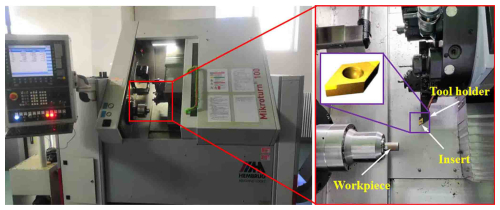

The precision cutting lathe used in this research was the Hembrug Mikroturn 100 (Netherlands), as shown in Fig. 1. The lathe adopts a hydrostatic spindle and hydrostatic guide rail, the maximum turning diameter is 380 mm, the hydrostatic spindle power is 7.5 kW, and the spindle speed can reach 10 000 r min−1. The Hembrug Mikroturn 100 is mainly used for precision turning of hardened materials, and its machining accuracy can reach the standard of precision grinding.

Cubic boron nitride (CBN) has high hardness, high wear resistance, and good chemical stability at high temperature (Tu et al., 2022). A CBN tool is considered the best tool for hard cutting, and it is very suitable for machining hardened steel with hardness greater than 50 HRC (Tu et al., 2023). Therefore, the tool material used for hard turning AISI M2 was cubic boron nitride. The insert is manufactured by Sandvik, with a negative chamfer on the rake face sized at −20° × 0.1 mm, a clearance angle of 7°, and a nose radius of 0.2 mm. It is worth noting that each tip of the CBN tool can be used for only one cutting to ensure the accuracy of tool wear and avoid interference with later experiments due to tool wear. The microscopic defects and white layer on the machined surface of the AISI M2 workpiece were observed and analysed by scanning electron microscopy. A laser scanning confocal microscope was used to measure the three-dimensional roughness of the AISI M2 workpiece. An x-ray residual stress analyser was used to measure the residual stress of the AISI M2 workpiece. A nano-indenter was used to analyse the microhardness of the AISI M2 workpiece.

2.2 Experimental scheme

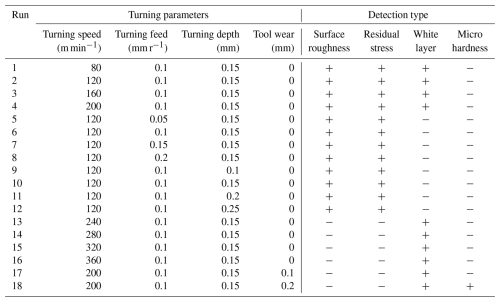

The selection of the cutting parameters for hard turning was carried out by referring to the recommendations of tool manufacturers and the suggestions of other scholars (Chung et al., 2022). The cutting speed for hard turning the AISI M2 workpiece was 80–200 m min−1, the cutting feed for hard turning AISI M2 was 0.05–0.2 mm r−1, and the cutting depth for hard turning AISI M2 was 0.1–0.25 mm. New CBN blades and CBN blades with wear of 0.1 and 0.2 mm were selected as the hard-turning tools. Table 1 shows the machining scheme of hard turning AISI M2. In Table 1, the symbol “+” indicates that the corresponding item was detected, and “–” indicates that the corresponding item was not measured.

3.1 Surface morphology analysis

The surface morphology of the workpiece includes regular surface microgeometric morphology and random surface defects (Liang et al., 2019). Surface roughness is often used to characterize the morphology of the machined surface, which is a key factor to measure the machining quality in the field of mechanical manufacturing (Danh and Cuong, 2023). Good surface roughness is helpful to improve the reliability of the workpiece. Bulaha (2015) thought that three-dimensional roughness was more comprehensive in characterizing the surface features of a workpiece. Todhunter et al. (2017) conducted an online questionnaire survey to analyse the use of three-dimensional roughness. The data came from 179 questionnaires in 34 countries. The results of the questionnaire showed that the most commonly used three-dimensional roughness parameter was arithmetic mean deviation Sa. Therefore, Sa was applied to describe the surface features of the AISI M2 workpiece.

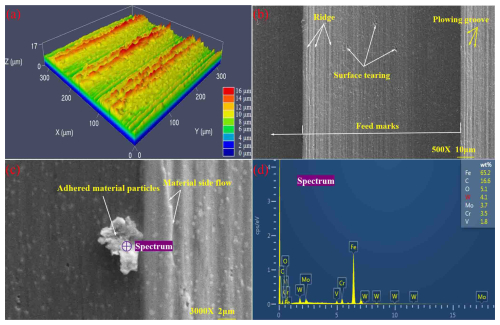

The peak and valley features of the AISI M2 workpiece surface had good regularity and consistency, as shown in Fig. 2a. However, there were micro-defects on the surface of the AISI M2 workpiece along the turning feed direction, such as ploughing grooves, material side flow, adhesive material particles, and surface tearing. These micro-defect features were proved as shown in Fig. 2b and c. Jouini et al. (2020) and Altan Özbek (2023) also found similar microscopic defect characteristics on the workpiece surface in the research of hard turning. The ploughing action of the tool on the surface of the workpiece, the scraping effect of the carbide falling off the workpiece, and the hard particles falling off the tool on the workpiece are all the reasons for the formation of the groove. The squeezing effect of the tool flank on the workpiece surface causes the groove to be plastically deformed, thus forming the material side flow defect. Broken chips adhere to the machined surface of the workpiece under high temperature, forming microscopic defects of adhesive particles. Figure 3d shows the energy spectrum of adhesive material particles. It can be found that the debris was consistent with the main elements contained in the AISI M2 workpiece, in which the contents of carbon and oxygen were very high. This also indicated that the adhesive material particles were oxidized at high temperature during the formation process. The high temperature and pressure generated in hard turning make the tiny materials of the workpiece surface bond with the tool. These tiny materials are detached from the workpiece surface under the cutting motion of the tool, thus forming microscopic defects of surface tearing. The above microscopic defects and their causes were also expounded in previous studies (Zhou et al., 2024).

Figure 2Surface morphology features of the AISI M2 workpiece. (a) Run 1; (b) surface defects (magnified by 500 times); (c) surface defects (magnified by 3000 times); (d) energy spectrum analysis.

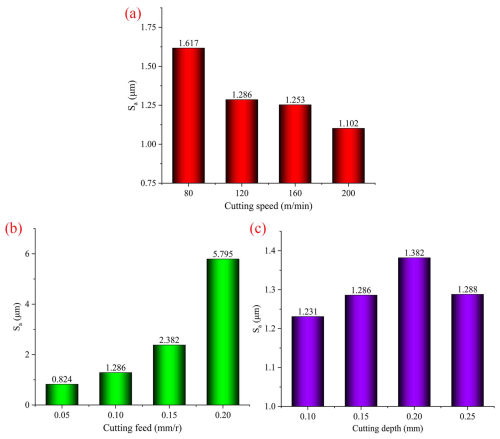

Figure 3Influence of turning parameters on three-dimensional surface roughness Sa of the AISI M2 workpiece. (a) Run 1 to Run 4; (b) Run 5 to Run 8; (c) Run 9 to Run 12.

The turning speed promoted the improvement in surface accuracy of the workpiece (Lima et al., 2005), as shown in Fig. 3a. When the turning speed during hard turning of the AISI M2 workpiece was 80 m min−1, its surface accuracy was the lowest, and the value of Sa was 1.617 µm. When the turning speed during hard turning of AISI M2 was 200 m min−1, the workpiece achieved the highest surface accuracy, and its Sa value was 1.102 µm. A high turning speed generates more cutting heat. The surface of the AISI M2 workpiece was softened by the high cutting heat generated during hard turning, so the cutting force during machining decreased, thus improving the machining accuracy of the workpiece surface. Turning feed is the primary factor affecting the surface accuracy of the workpiece (Dureja et al., 2009). As illustrated in Fig. 3b, the improvement in turning feed during hard turning of AISI M2 significantly reduced its surface accuracy. When the turning feed during hard turning of AISI M2 was changed from 0.05 to 0.2 mm r−1, its Sa increased from 0.824 to 5.795 µm. The increase in turning feed not only leads to the increase in the microscopic residual height on the surface of the workpiece but also increases the cutting force (Bartarya and Choudhury, 2012), which makes the workpiece vibrate during machining. Turning depth had little influence on the surface accuracy of the AISI M2 workpiece, and Sa firstly increased and then decreased, as shown in Fig. 3c. When the turning depth during hard turning of AISI M2 was 0.1 mm, its Sa was 1.231 µm, and the surface accuracy was the highest. When the turning depth during hard turning of AISI M2 was 0.2 mm, the surface roughness of the machined surface was the worst, and its value Sa was 1.382 µm.

3.2 Surface metamorphic layer analysis

A metamorphic layer is produced on the machined surface of the workpiece under severe thermal–mechanical combined load. The metamorphic layer is a white layer between 0.1 and 100 µm. The white layer has excellent corrosion resistance, high hardness, and high brittleness, and there are random microcracks in it. The white layer formation fundamentally depends on the thermal and mechanical effects experienced by the workpiece material during machining. A high machining speed usually causes a high deformation rate of the material in the machining shear zone, thus generating massive cutting heat and transferring it to the workpiece. The gradual wear of the tool intensifies the friction between it and the workpiece, thus increasing the heat output and shear distortion on the surface of the workpiece.

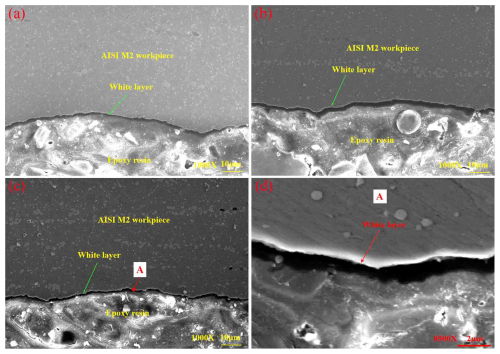

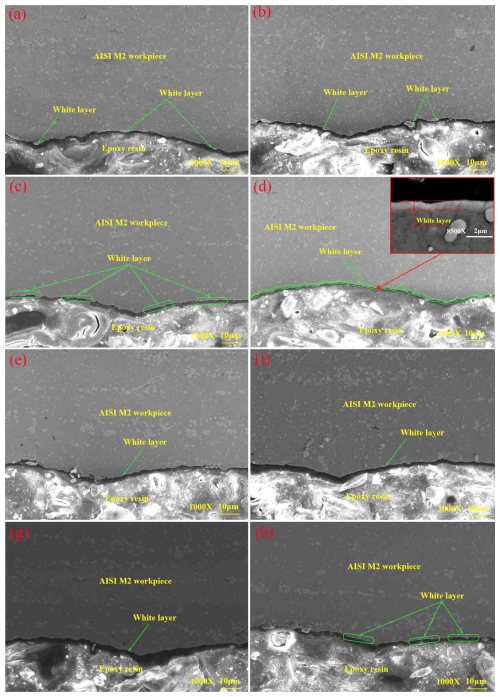

3.2.1 Influence of turning speed on the white layer

There was a negligible amount of white layer on the machined surface of the AISI M2 workpiece in Run 1 and Run 2, as shown in Fig. 4a and b. Although the white layer of Run 3 was still intermittent, its continuity relatively increased, as shown in Fig. 4c. The pattern of the white layer in Run 4 was continuous, the average value of the white layer was taken after many measurements, and its thickness was about 0.32 µm, as shown in Fig. 4d. From Run 13 to Run 15, although the thickness of the white layer fluctuated, the overall change trend of the white layer was still continuous, as shown in Fig. 4e to g. The white layer pattern of Run 16 returned to the intermittent state, as shown in Fig. 4h. That is to say, when the turning speed was 80–200 m min−1, the thickness of the white layer increased with the increase in turning speed, and there was a positive correlation between them. When the turning speed was 200–360 m min−1, the thickness of the white layer decreased with the increase in turning speed, and there was a negative correlation between them. The influence of turning speed on the thickness of the white layer was similar to the research results of other studies (Bartarya and Choudhury, 2012; Fang-yuan et al., 2018). When the turning speed was 80–160 m min−1, there was a discontinuous trace of white layer structure on the machined surface, and its thickness was approximately 0. When the turning speed during hard turning of AISI M2 reached 360 m min−1, the thickness of the white layer was almost 0.

Figure 4Influence of turning speed on the white layer of the AISI M2 workpiece. (a) Run 1; (b) Run 2; (c) Run 3; (d) Run 4; (e) Run 13; (f) Run 14; (g) Run 15; (h) Run 16.

An increase in turning speed leads to an increase in cutting heat (Czan et al., 2017), while the influence of the turning speed on the cutting force is relatively small (Chenwei et al., 2019). When the turning speed was low (80–200 m min−1), the friction time between the tool flank and the machined surface was longer, and more heat was transmitted into the material. Cutting heat and cutting force jointly facilitated the plastic deformation and phase transformation of the machined surface of the workpiece, thus increasing the thickness of the white layer on the machined surface. When the turning speed was high (200–360 m min−1), the friction time between the tool flank and the workpiece material became shorter, and more cutting heat was transmitted to the air by chips, so the thickness of the white layer tended to decrease.

3.2.2 Influence of tool wear on the white layer

The increase in tool wear improves the cutting force and cutting heat in hard turning and promotes the generation of the white layer (Klocke et al., 2005). The white layer in Fig. 5 was continuous, and it became more obvious as the tool wear intensified. When the CBN tool for hard turning AISI M2 was a new tool, a tool with wear of 0.1 mm, and a tool with wear of 0.2 mm, the corresponding white layer thickness was about 0.32, 0.46, and 0.78 µm, respectively. The wear of the CBN tool used in hard turning AISI M2 was from 0 to 0.2 mm, and its white layer thickness increased by 143.75 %. This indicated that the tool wear aggravated the occurrence of the white layer.

3.3 Surface mechanical properties analysis

The surface mechanical properties of workpieces mainly include surface hardness and surface residual stress. During the precision machining process of hard turning, the workpiece material is subjected to both mechanical load and thermal load, resulting in residual stress and microhardness changes on the surface of the workpiece.

3.3.1 Residual stress of the machined surface

The residual stress on the machined surface has a great influence on the geometric accuracy stability, fatigue strength, and corrosion resistance of the workpiece (Poulachon et al., 2005). The compressive or tensile properties of the residual stress can be beneficial or harmful (Khoshaim et al., 2021). Therefore, the residual stress generated in the process of hard-turning precision machining is worthy of attention. Elsheikh et al. (2020) pointed out that hard turning produced compressive residual stress on the workpiece surface.

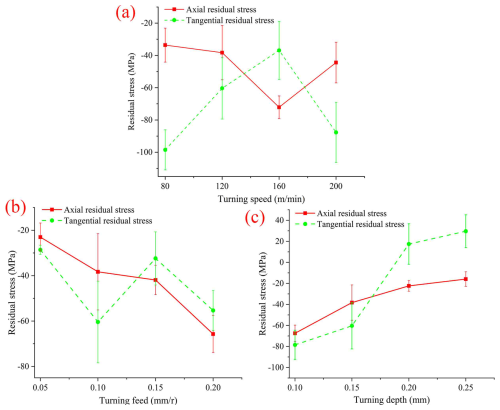

Figure 6Influence of turning parameters on the surface residual stress of the AISI M2 workpiece. (a) Run 1 to Run 4; (b) Run 5 to Run 8; (c) Run 9 to Run 12.

The effect of turning speed on residual stress on the surface of the AISI M2 workpiece is shown in Fig. 6a. When the turning speed during hard turning of AISI M2 increased from 80 to 160 m min−1, the axial residual stress gradually improved, while the tangential residual stress showed an opposite trend. As the turning speed was increased from 160 to 200 m min−1, the axial residual stress was gradually reduced, and the tangential residual stress was gradually elevated. The maximum axial residual stress and the minimum tangential residual stress on the machined surface of AISI M2 appeared at the turning speed of 160 m min−1, and their values were −72.1 ± 7 and −36.9 ± 18 MPa, respectively. Within the range of the turning speed, the residual stress was compressed in both the axial and tangential directions. The effect of turning feed on residual stress on the surface of the AISI M2 workpiece is shown in Fig. 6b. The improvement in turning feed promoted the rise in axial residual stress. The component of the residual stress in the tangential direction fluctuated with the change in the turning feed, and the regularity was not obvious. When the turning feed during hard turning of AISI M2 was 0.05 mm r−1, the residual stress was the smallest in the tangential direction, and its value was −28.6 ± 2 MPa. When the turning feed during hard turning of AISI M2 was 0.1 mm r−1, the residual stress was the largest in the tangential direction, and its value was −60.4 ± 22 MPa. Within the range of turning feed parameters, the components of the residual stress in the axial and tangential directions were compressive stress. Figure 6c illustrates the effect of turning depth on residual stresses on the surface of the AISI M2 workpieces. With the improvement in turning depth, the residual stress in the axial and tangential directions tended to change from the compressed state to the tensile state.

3.3.2 Microhardness of the machined surface

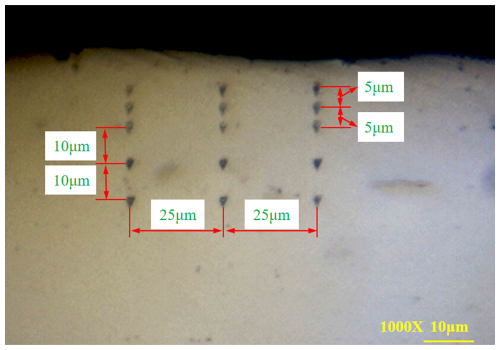

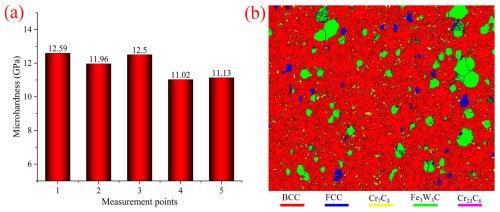

Many scholars (Paengchit and Saikaew, 2023) have studied the microhardness change of the machined surface of the workpiece in hard turning and reached a universal conclusion: the microhardness of the white layer is obviously higher than that of the matrix material. The white layer is very thin, which makes the microhardness value often misleading, and it is often noticed that there is a big unexpected change in the microhardness value (Mičietová et al., 2023). The detection mode of the nano-indenter was a continuous stiffness pattern, and the position of its detection point is shown in Fig. 7. The vertical distance between the first and third detection points was 5 µm, and the vertical distance between the third and fifth detection points was 10 µm. In order to reduce the measurement error, the microhardness was continuously measured three times, and the measurement distance was 25 µm each time.

Figure 8Microhardness of the AISI M2 workpiece. (a) Microhardness of different detection points. (b) Distribution of carbides in the AISI M2 workpiece.

The microhardness of the AISI M2 workpiece surface is shown in Fig. 8a. The change in microhardness was random and had no obvious regularity. This was mainly due to the random distribution of carbides with high hardness in the AISI M2 matrix. The distribution of high-hardness carbides of the AISI M2 material detected by EBSD is shown in Fig. 8b. The thickness of the white layer formed by hard-turning precision machining of AISI M2 was far less than 1 µm, and the distance between the first indentation point and the surface was more than 1 µm, so it was difficult to capture the mechanical properties of the white layer (Bertolini et al., 2020); thus, the hardness of the white layer could not be reflected in Fig. 8a.

Based on an analysis of the surface characteristics of AISI M2 workpieces after hard turning, the present study drew the following conclusions:

- 1.

The surface morphology of workpieces machined by hard turning was found to exhibit good regularity and consistency, while micro-defects such as ploughing groove, material side flow, adhered material particles, and surface tearing were observed. The turning feed was shown to have the most significant impact on the three-dimensional surface roughness Sa: when the feed rate was increased from 0.05 to 0.2 mm r−1, Sa surged from 0.824 to 5.795 µm.

- 2.

When the turning speed was lower than 200 m min−1, the white layer thickness was positively correlated with the speed (approximately 0.32 µm at 200 m min−1); when it was higher than 200 m min−1, a negative correlation was observed (approximately 0 at 360 m min−1). When the tool wear was increased from 0 mm to 0.2 mm, the white layer thickness was increased from 0.32 to 0.78 µm, with an increase rate of 143.75 %.

- 3.

The residual stress generated by hard turning was mainly compressive, with the maximum axial compressive stress (−72.1 ± 7 MPa) observed at a cutting speed of 160 m min−1. The presence of the metamorphic layer significantly increased the surface hardness, while the random distribution of carbides in the matrix resulted in no obvious regularity in the variation of microhardness.

No data sets were used in this study.

TZ: conceptualization, methodology, investigation, and writing. LZ: resources and data curation. TC: supervision. JL: project administration.

The contact author has declared that none of the authors has any competing interests.

Publisher's note: Copernicus Publications remains neutral with regard to jurisdictional claims made in the text, published maps, institutional affiliations, or any other geographical representation in this paper. While Copernicus Publications makes every effort to include appropriate place names, the final responsibility lies with the authors. Views expressed in the text are those of the authors and do not necessarily reflect the views of the publisher.

The authors would like to acknowledge the support provided by Changchun Equipment and Technology Research Institute for the experiments conducted in this study.

This research has been supported by the Research on Precision Machining Technology of Quenched High Speed Steel (Beijing Muxi Technology Co., Ltd.) (grant no. HX2025007000) and Scientific Research Project of Fuyang Normal University (grant no. 2024KYQD0098).

This paper was edited by Zbigniew Gronostajski and reviewed by two anonymous referees.

Altan Özbek, N.: Effects of Shallow and Deep Cryogenic Treatment on Tool Flank Wear and Surface Roughness in Machining 41Cr4 Steel, J. of Materi. Eng. and Perform., 32, 9638–9648, https://doi.org/10.1007/s11665-023-07866-w, 2023.

Bartarya, G. and Choudhury, S. K.: Effect of cutting parameters on cutting force and surface roughness during finish hard turning AISI52100 grade steel, Procedia CIRP, 1, 651–656, https://doi.org/10.1016/j.procir.2012.05.016, 2012.

Bertolini, R., Bedekar, V., Ghiotti, A., and Bruschi, S.: Surface integrity and corrosion performances of hardened bearing steel after hard turning, Int. J. Adv. Manuf. Technol., 108, 1983–1995, https://doi.org/10.1007/s00170-020-05352-4, 2020.

Branco, F. K., Delijaicov, S., Bordinassi, É. C., and Bortolussi, R.: Surface integrity analisys in the hard turning of cemented steel AISI 4317, Mat. Res., 21, e20171032, https://doi.org/10.1590/1980-5373-MR-2017-1032, 2018.

Bulaha, N.: Analysis of service properties of cylindrically ground surfaces, using standard ISO 25178-2: 2012 surface texture parameters, in: Environment. Technologies. Resources, Proceedings of the 10th International Scientific and Practical Conference, 1, 16–21, https://doi.org/10.17770/etr2015vol1.228, 2015

Cakan, A., Albayrak, O., Sanli, B. G., Guven, O., Ugurlu, M., and Atmaca, H.: Cutting performance of coated carbide inserts in hard turning of hardened AISI D2 cold work tool steels, P. I. Mech. Eng. C-J. Mec., 238, 9504–9513, https://doi.org/10.1177/09544062241257421, 2024.

Çetindağ, H. A., Çiçek, A., and Aslantas, K.: Performance of conventional and wiper CBN inserts under various cooling conditions in hard turning of AISI 52100 steel, Mater. Test., 66, 288–298, https://doi.org/10.1515/mt-2023-0263, 2024.

Chenwei, S., Zhang, X., Bin, S., and Zhang, D.: An improved analytical model of cutting temperature in orthogonal cutting of Ti6Al4V, Chinese J. Aeronaut., 32, 759–769, https://doi.org/10.1016/j.cja.2018.12.001, 2019.

Chung, C., Wang, P.-C., and Chinomona, B.: Optimization of turning parameters based on tool wear and machining cost for various parts, Int. J. Adv. Manuf. Technol., 120, 5163–5174, https://doi.org/10.1007/s00170-022-09037-y, 2022.

Czan, A., Sajgalik, M., Holubjak, J., and Martikan, P.: Identification of temperatures in cutting zone when dry machining of nickel alloy Inconel 718, Procedia Manufacturing, 14, 66–75, https://doi.org/10.1016/j.promfg.2017.11.008, 2017.

Danh, B. T. and Cuong, N. V.: Surface Roughness Modeling of Hard Turning 080A67 Steel, Eng. Technol. Appl. Sci., 13, 10659–10663, https://doi.org/10.48084/etasr.5790, 2023.

Dash, L., Padhan, S., Das, A., and Das, S. R.: Machinability investigation and sustainability assessment in hard turning of AISI D3 steel with coated carbide tool under nanofluid minimum quantity lubrication-cooling condition, P. I. Mech. Eng. C-J. Mec., 235, 6496–6528, https://doi.org/10.1177/0954406221993844, 2021.

Dureja, J., Gupta, V., Sharma, V., and Dogra, M.: Design optimization of cutting conditions and analysis of their effect on tool wear and surface roughness during hard turning of AISI-H11 steel with a coated–mixed ceramic tool, P. I. Mech. Eng. B-J. Eng., 223, 1441–1453, https://doi.org/10.1243/09544054JEM1498, 2009.

Elsheikh, A. H., Guo, J., and Lee, K.-M.: Improving clamping accuracy of thin-walled workpiece in turning operation, IOP Conf. Ser.-Mat. Sci., 751, 012080, https://doi.org/10.1088/1757-899X/751/1/012080, 2020

Elsheikh, A. H., Shanmugan, S., Thakur, A. K., Essa, F., Ibrahim, A. M. M., and Mosleh, A. O.: A comprehensive review on residual stresses in turning, Adv. Manuf., 10, 287–312, https://doi.org/10.1007/s40436-021-00371-0, 2022.

Fang-yuan, Z., Chun, D., Xin, X., and Min, W.: Influence of cutting condition on white layer induced by high speed machining of hardened steel, Int. J. Adv. Manuf. Technol., 98, 77–84, https://doi.org/10.1007/s00170-017-0454-3, 2018.

Hacisalihoglu, I., Yildiz, F., and Alsaran, A.: Wear performance of different nitride-based coatings on plasma nitrided AISI M2 tool steel in dry and lubricated conditions, Wear, 384, 159–168, https://doi.org/10.1016/j.wear.2017.01.117, 2017.

Jouini, N., Revel, P., and Thoquenne, G.: Influence of surface integrity on fatigue life of bearing rings finished by precision hard turning and grinding, J. Manuf. Process., 57, 444–451, https://doi.org/10.1016/j.jmapro.2020.07.006, 2020.

Khoshaim, A. B., Elsheikh, A., Moustafa, E., and Basha, M.: Prediction of residual stresses in turning of pure iron using artificial intelligence-based methods, J. Mater. Res. Technol., 11, 2181–2194, https://doi.org/10.1016/j.jmrt.2021.02.042, 2021.

Klocke, F., Brinksmeier, E., and Weinert, K.: Capability profile of hard cutting and grinding processes, CIRP Annals, 54, 22–45, https://doi.org/10.1016/S0007-8506(07)60018-3, 2005.

Li, B., Zhang, S., and Jiang, D.: Influence of edge hone radius on cutting forces, surface integrity, and surface oxidation in hard milling of AISI H13 steel, Int. J. Adv. Manuf. Technol., 95, 1153–1164, https://doi.org/10.1007/s00170-017-1292-z, 2018.

Liang, X., Liu, Z., and Ren, X.: Investigation of surface topography and its deterioration resulting from tool wear evolution when dry turning of titanium alloy Ti-6Al-4V, Tribol. Int., 135, 130–142, https://doi.org/10.1016/j.triboint.2019.02.049, 2019.

Lima, J., Avila, R., Abrao, A., Faustino, M., and Davim, J. P.: Hard turning: AISI 4340 high strength low alloy steel and AISI D2 cold work tool steel, J. Mater. Process. Tech., 169, 388–395, https://doi.org/10.1016/j.jmatprotec.2005.04.082, 2005.

Mane, S., Patil, R. B., and Al-Dahidi, S.: Predictive modeling of surface roughness and cutting temperature using response surface methodology and artificial neural network in hard turning of AISI 52100 steel with minimal cutting fluid application, Machines, 13, 266, https://doi.org/10.3390/machines13040266, 2025.

Mičietová, A., Čilliková, M., Čep, R., Neslušan, M., and Ganev, N.: Study of Residual Stresses and Austenite Gradients in the Surface after Hard Turning as a Function of Flank Wear and Cutting Speed, Materials, 16, 1709, https://doi.org/10.3390/ma16041709, 2023.

Paengchit, P. and Saikaew, C.: Simulation of the influence of cutting speed and feed rate on tool life in hard turning of AISI 4140 steel, Mater. Sci. Pol., 41, 311–324, https://doi.org/10.2478/msp-2023-0021, 2023.

Poulachon, G., Albert, A., Schluraff, M., and, Jawahir, I. S.: An experimental investigation of work material microstructure effects on white layer formation in PCBN hard turning, Int. J. Mach. Tool Manu., 45, 211–218, https://doi.org/10.1016/j.ijmachtools.2004.07.009, 2005.

Sales, W. F., Schoop, J., Silva, L. R., Machado, Á. R., and Jawahir, I. S.: A review of surface integrity in machining of hardened steels, J. Manuf. Process., 58, 136–162, https://doi.org/10.1016/j.jmapro.2020.07.040, 2020.

Sivalingam, V., Zhao, Y., Thulasiram, R., Sun, J., and Nagamalai, T.: Machining behaviour, surface integrity and tool wear analysis in environment friendly turning of Inconel 718 alloy, Measurement, 174, 109028, https://doi.org/10.1016/j.measurement.2021.109028, 2021.

Todhunter, L. D., Leach, R. K., Lawes, S. D., and Blateyron, F.: Industrial survey of ISO surface texture parameters, CIRP J. Manuf. Sci. Tec., 19, 84–92, https://doi.org/10.1016/j.cirpj.2017.06.001, 2017.

Tu, L., Lin, L., Yang, Z., An, Q., Ming, W., and Chen, M.: Wear behaviors of cubic boron nitride tools with various binders in high-speed turning of compacted graphite irons, Wear, 504, 204417, https://doi.org/10.1016/j.wear.2022.204417, 2022.

Tu, L., Lin, L., Liu, C., Zheng, T., Deng, Y., Han, L., and Chen, M.: Tool wear characteristics analysis of cBN cutting tools in high-speed turning of Inconel 718, Ceram. Int., 49, 635–658, https://doi.org/10.1016/j.ceramint.2022.09.034, 2023.

Zhang, S., Liu, Z., Wang, B., Ren, X., Khan, A. M., and Zhao, M.: Phase transition and dynamic recrystallization mechanisms of white layer formation during turning superalloy Inconel 718, J. Mater. Res. Technol., 15, 5288–5296, https://doi.org/10.1016/j.jmrt.2021.11.004, 2021.

Zhang, T., Wang, Q., Wang, N., Yan, L., Jiang, F., Zhang, E., Zhou, W., Gao, H., and Wang, Y.: Surface Integrity in the Grinding of Hardened AISI D2 Steel, Materials, 18, 814, https://doi.org/10.3390/ma18040814, 2025.

Zhou, T., Wu, Q., Wang, Z., Zhao, G., and Wu, H.: Analysis of machined surface topography of AISI M2 in hard turning based on Box-Behnken Design, P. I. Mech. Eng. B-J. Eng., 238, 58–71, https://doi.org/10.1177/09544054231157261, 2024.